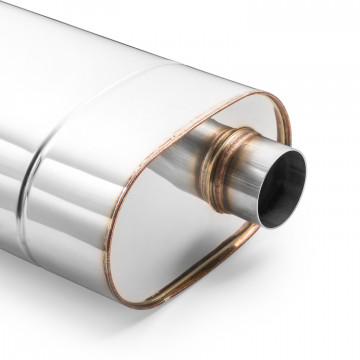

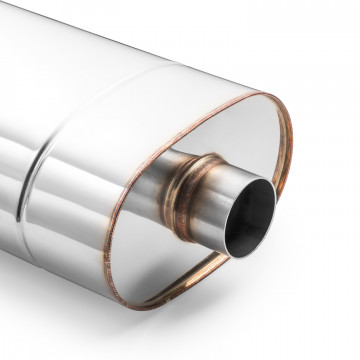

End silencer BMW E39 M5 5.0 V8 2000-2003 to weld

EM002/63/350

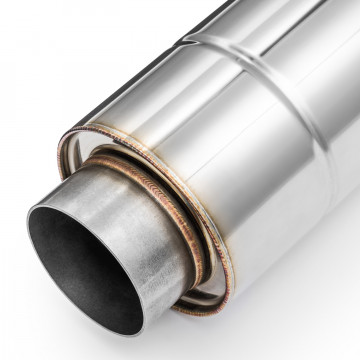

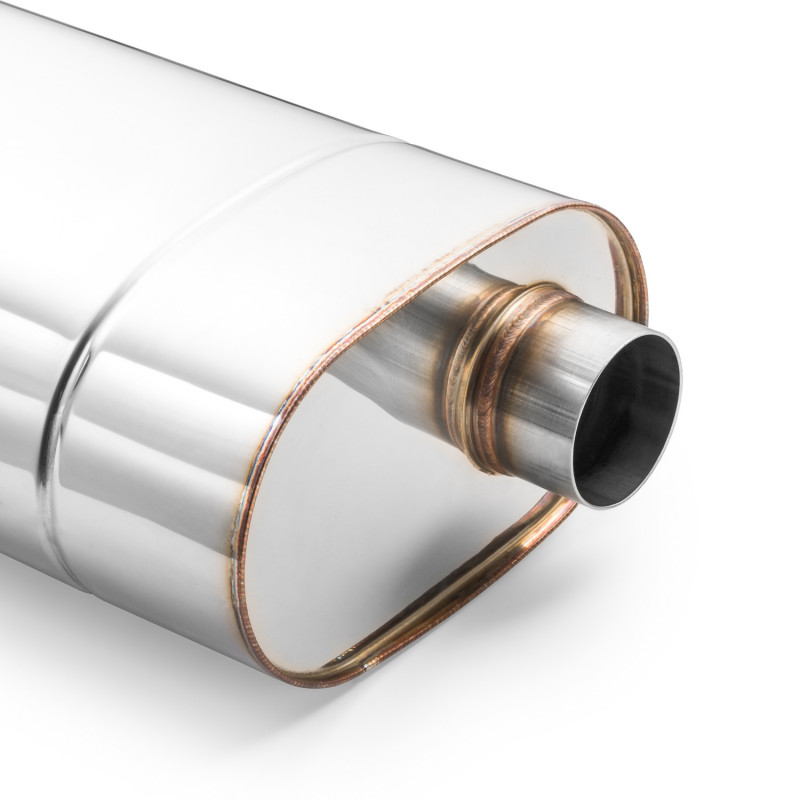

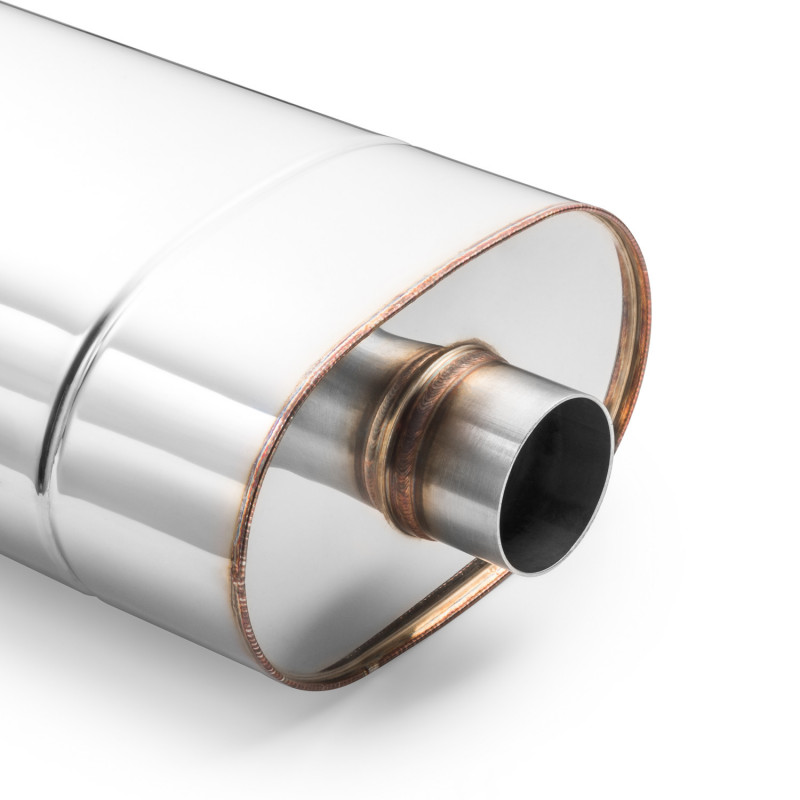

Muffler ready to weld in the place of the original one. Pipe diameter, dimensions of the muffler box and its length are selected in such a way so that the silencer assembly is as easy as possible.

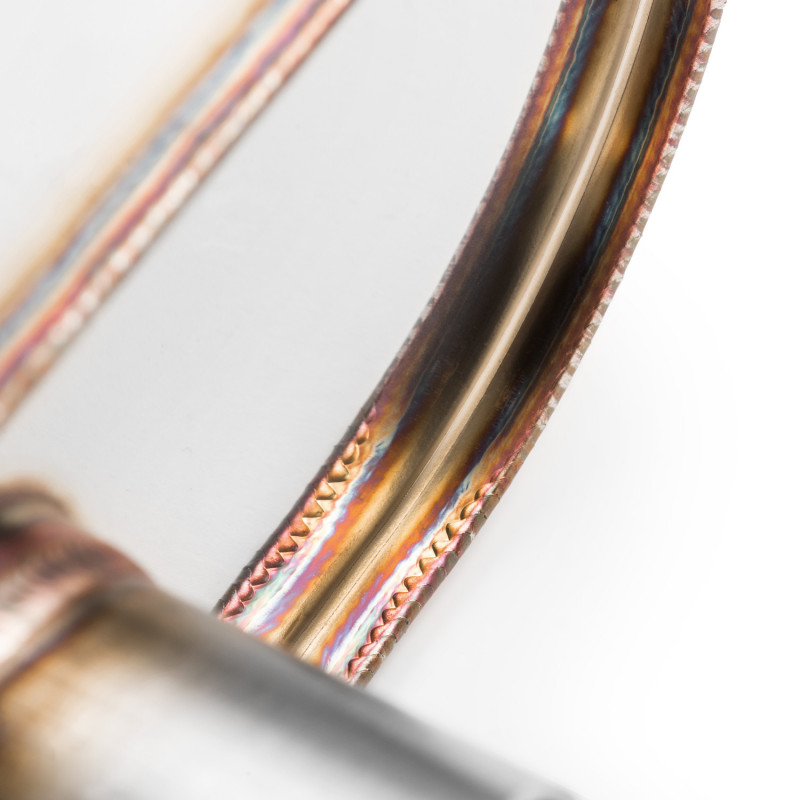

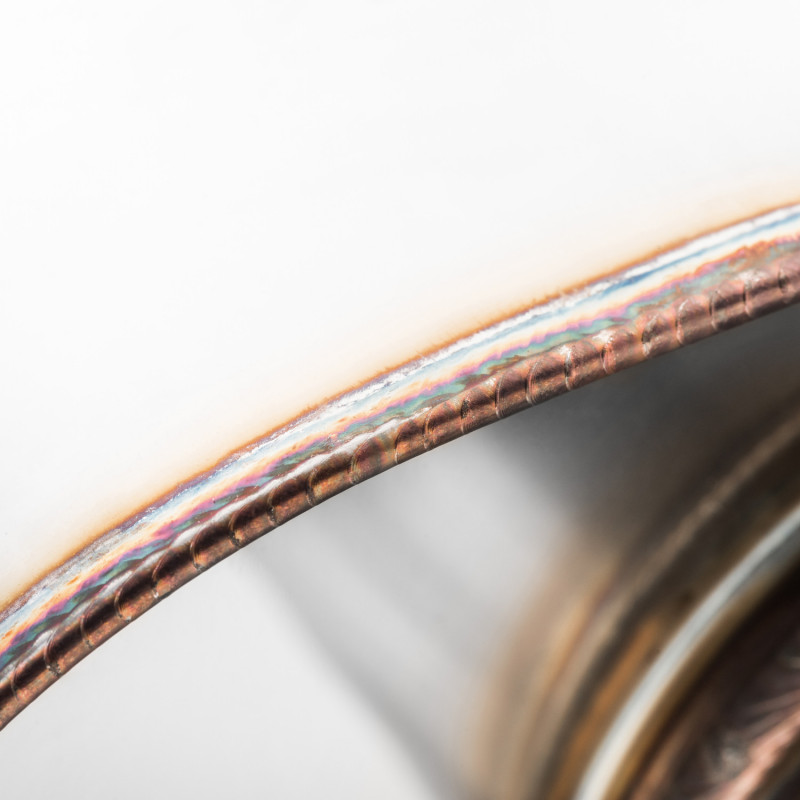

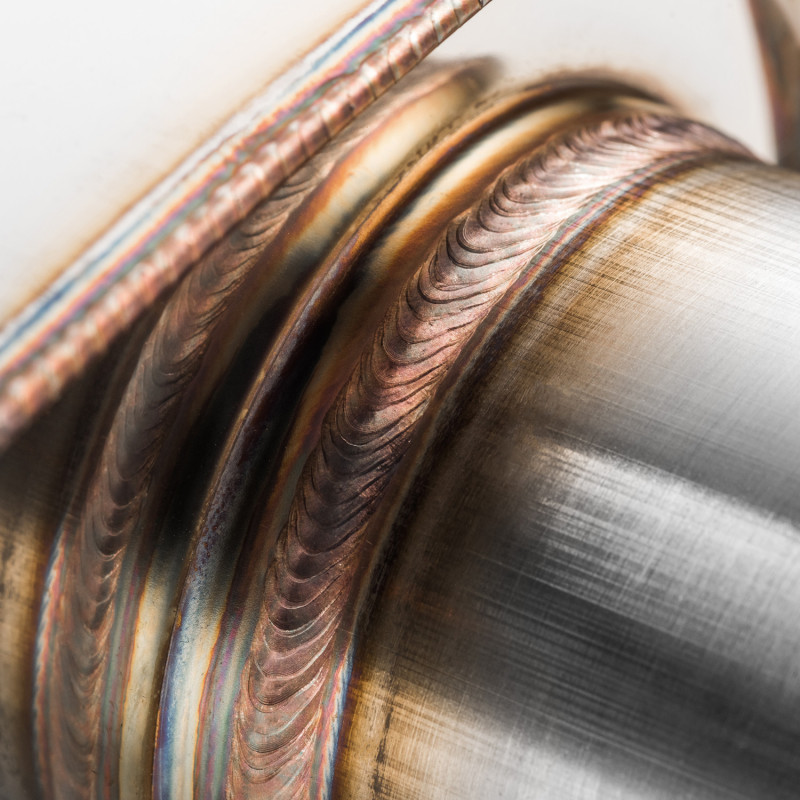

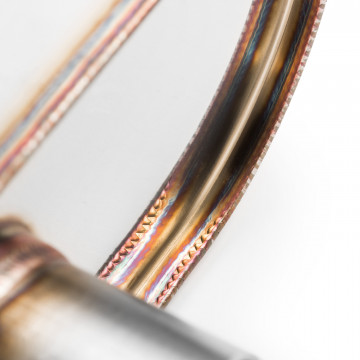

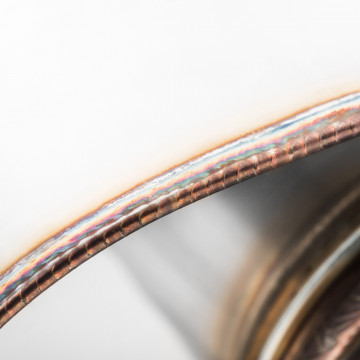

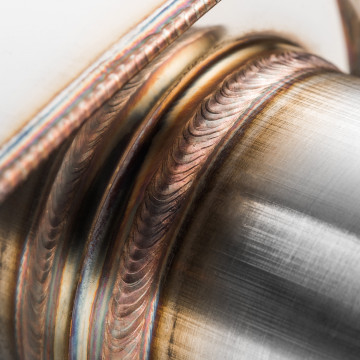

A silencer with a straight-through construction, damped with stainless steel wool and a glass mat resistant to 800 degrees Celsius (glass mat made of full hair - we do not use scraps). Fully welded by welding robot, hand finished. Each element of the product is made using CNC technology. Crack-resistant embossed bottoms have been used.

Muffler dimensions:

Can length - 350 mm

Pipe diameter - 63.5 mm

Can dimensions - 100x180 mm

The product is not homologated and cannot be approved for use on public roads in the EU.

36 rat x ~20 zł

36 rat x ~20 zł